Paper

Talc plays an important role in modern papermaking as a widely used functional filler. By filling the voids between paper fibers, it helps produce paper with a smoother and more uniform surface, while enhancing opacity and whiteness for improved print quality. Products such as Jinghua New Materials’ SK series also contribute to better softness, bulk, and flexibility, improving the overall feel and performance of the paper. In addition, talc can partially replace costly fiber raw materials, reducing production costs without compromising quality. Its chemical stability ensures compatibility with other papermaking additives, supporting consistent and reliable operation throughout the process. With these advantages, talc supports the paper industry in achieving higher efficiency, better product performance, and more sustainable development.

View Details About Company

About Company Production Workshops

Production Workshops R&D and Test Center

R&D and Test Center Industrial Grade Talc

Industrial Grade Talc Modified Plastics

Modified Plastics Rubber

Rubber Paints & Coatings

Paints & Coatings Paper

Paper Honeycomb Ceramic

Honeycomb Ceramic EVA Foam (Shoe Materials)

EVA Foam (Shoe Materials) Food Industry

Food Industry Cosmetic Grade Talc

Cosmetic Grade Talc Cable & Wire

Cable & Wire HDPE

HDPE Building & Construction

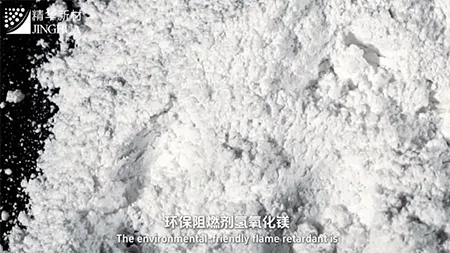

Building & Construction Magnesium Hydroxide Flame Retardant

Magnesium Hydroxide Flame Retardant PP Filler Masterbatch

PP Filler Masterbatch Masterbatch Applications in Action

Masterbatch Applications in Action Functional Masterbatch Production Process

Functional Masterbatch Production Process